Removal

- Remove the wheel (refer to procedure).

- Remove the cap and inner core from the valve to deflate the tire.

Note: Use a suitable tire-removing machine for the following steps.

Note: Check direction of tire machine rotation before starting

procedure.

-

Release the tire beading from the wheel on both sides.

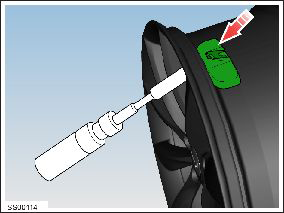

Caution: Ensure that the machine is away from the valve and sensor.Caution: The TPMS wheel sensor can be damaged if the instructions are not followed correctly.

- Apply a suitable lubricant to each tire bead.

- Position and secure the wheel on the tire machine with the front face up.

-

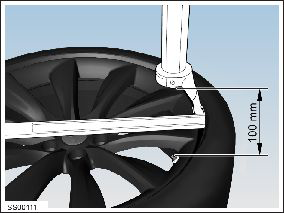

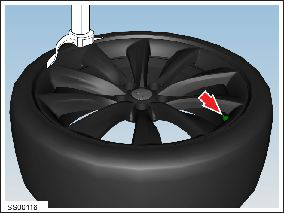

Rotate the wheel and tire so that the mounting head is 100 mm in front of the

valve. Using a tire lever, lift the tire bead onto the mounting head.

Note: Ensure that the tire bead does not slip on the wheel during removal/installation.

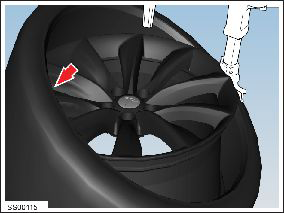

- Release the tire bead from the wheel by rotating the machine.

-

Rotate the wheel and tire so that the mounting head is 100 mm in front of the

valve. Using a tire lever with a wheel protector, lift the bottom tire bead onto

the mounting head.

Note: Ensure that the tire bead does not slip on the wheel during removal/installation.

- Release the tire bead from the wheel by rotating the machine and remove the tire. Do not remove the tire lever; it will stop the tire from sliding back and could damage the sensor.

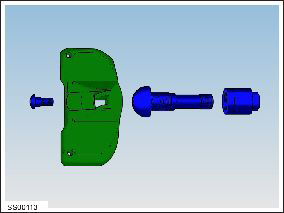

- Remove the nut that secures the valve to the wheel. Remove both the valve and wheel sensor.

- Remove and discard the valve and screw from the wheel sensor.