Removal

- Recover refrigerant from the vehicle (refer to procedure).

- Remove the wiper arms (refer to procedure).

- Remove the 12V battery bracket beam (refer to procedure).

- Ensure that the cap on the reservoir is properly secured.

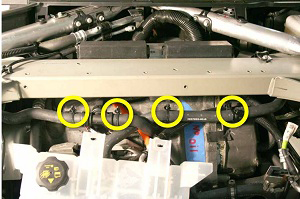

- Release the 4 bolts that secure the coolant reservoir to the front crossmember (torque 6 Nm). Do not remove the reservoir at this time.

Note: At this point in the procedure, there are still 2 coolant hoses and 1 harness

attached to the reservoir.

- Carefully lift up the coolant reservoir and disconnect the coolant level sensor harness.

-

Pull the reservoir forward into the underhood area.

Note: The reservoir hose is routed behind the hose that connects to the gearbox. Note the routing of the hoses and ensure that they are routed correctly during reinstallation.

- Gently pull down on the 2 coolant hoses to release the clips (x4) that secure them to the front crossmember.

- Release the clip that secures the coolant reservoir hose to the A/C line.

- On the LH side of the 3-way fitting, clamp the coolant hose that leads to the differential housing. Remove the hose from the front drive unit and and plug the nipple.

-

Move the coolant reservoir to the LH side of the vehicle and secure it out of

the working area.

Caution: The reservoir is still secured to 2 coolant hoses.

- Remove the LH and RH shock tower to bulkhead struts (refer to procedure).

- Release the bolts (x2) that secure the LH fuse box to the crossmember (torque 5 Nm).

-

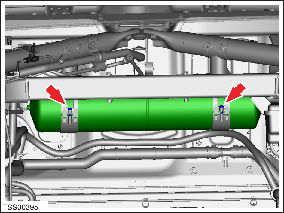

If the vehicle is equipped with air suspension, release the bolts (x2) that

secure the air reservoir (torque 2.5 Nm). Carefully set the reservoir in the RH

side of the underhood area.

Note: It is not necessary to disconnect the air lines.

- Disconnect the compressor connector from the forward junction box (FJB).

- Release the clip that secures the LH A/C line to the compressor HV harness.

- Release the 2 nuts that secure the A/C lines to the compressor. Plug both holes and cap both lines.

- Disconnect the compressor LV harness.

- Release the ground strap from the A/C compressor bracket (torque 7 Nm).

- Release the edge clip that secures the LV harnesses to the compressor bracket.

- Release the fir tree clip that secures the LV harnesses to the top of the front drive unit.

-

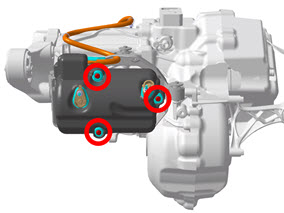

Release the bolts (x3) that secure the compressor to the bracket (torque 20

Nm).

Caution: Do not spill oil from the compressor when removing it. The amount of oil remaining in the old compressor needs to be measured when the new compressor is installed.

- Remove the acoustic cover from the compressor.