Alignment Check

- Raise the alignment platform until it is clear of all 4 rack locks.

- Lower the alignment platform onto the rack locks and ensure that it is level.

- Secure all 4 alignment optical targets.

- Perform the rolling compensation.

- Remove the pins from the slip plates and turn plates.

-

Air suspension only: Check the ride height:

- If the fasteners that

secure a subframe, ride height sensor, ride height sensor bracket, front

upper control arm, or rear camber link have been loosened or removed:

- Select Normal in the Toolbox "Air Suspension Leveling" panel.

- Place the

measuring tool on the platform, then measure the distance from

the platform to the bolt head (front corners) or tip of the bolt

(rear corners).

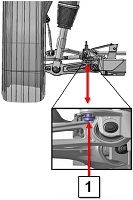

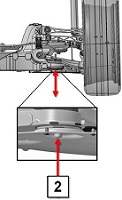

Front Suspension (rearmost subframe bolt, rear view, left side) Rear Suspension (front subframe bolt, front view, left side) 1 Measure to center of bolt head 2 Measure to center of bolt end tip - Record the measured ride heights for each corner.

- In Toolbox, refer

to the "Ride Height" panel. Subtract the ride height shown by

Toolbox from the measured ride height for each corner. Refer to

the example below.Note: If the Toolbox ride height is a negative number, add it to the physical measurement. If the Toolbox ride height is a positive number, subtract it from the physical measurement.

Table 1. Example Only Left Front Right Front Left Rear Right Rear Physical measurement 213 208 140 143 Toolbox ride height -2 +3 +1 -4 Total (physical measurement - Toolbox ride height) 215 205 139 147 - Compare the total

heights of each corner to the ride height specifications:

General Information > Technical Data > Wheel Alignment.

Left Front Right Front Left Rear Right Rear Total from previous step 215 205 139 147 Specification 213.5 +/- 5 213.5 +/- 5 144 +/- 5 144 +/- 5 Result Pass Fail Pass Pass Note: The specification shown is an example. Refer to General Information > Technical Data > Wheel Alignment for the proper specifications.Note: The specification shown is an example. Refer to General Information > Technical Data > Wheel Alignment for the proper specifications. - If the total of

any value is outside of the specifications, perform a ride

height calibration (refer

to procedure).Note: The ride height calibration is not included in the four wheel alignment check correction code. Add the ride height calibration correction code separately.

- If none of the above

fasteners have been loosened or removed:

- In Toolbox, select Views > Suspension > Air Suspension Leveling, then run the Cycle Heights High > Normal routine.

- In Toolbox, select Views > Suspension > Ride Height.

- Check that each level is between -5 mm and +5 mm.

- If any level is not between -5 mm and +5 mm, run the Cycle Heights High > Normal routine again.

- If any level is not between -5 mm and +5 mm, run the Cycle Heights High > Normal routine again.

- If the fasteners that

secure a subframe, ride height sensor, ride height sensor bracket, front

upper control arm, or rear camber link have been loosened or removed:

Note: Do not bump or pull on the vehicle for the remainder of this

procedure; this could bring the ride height values out of

specification.

- Install the brake pedal depressor.

- Perform a caster sweep without sitting inside or leaning on the vehicle.

- Turn the steering wheel so that the steering wheel angle displayed on the touchscreen is 0.0 degrees, then install the steering wheel holder.

Note: If the alignment machine

indicates that all parameters are within specification, the vehicle passes

the alignment check. Continue to the next step.

Note: If the vehicle fails the

alignment check, perform a full alignment (refer to procedure) and add the appropriate

correction code for "Four Wheel Alignment - Adjust Only":

- Air Suspension:31002100

- Coil Suspension:31002200

- Transfer the PDF of the alignment results from the alignment machine and attach it to the repair order.

- Remove the brake pedal depressor.

-

Reinstall all slip plate pins and turn plate pins.

Tip: Install the forward slip plate pins before installing the rearward slip plate pins.

- Remove all 4 alignment optical targets.

- Enter the vehicle.

- Press the brake pedal and shift into Park.

- Remove the wheel chocks.

- Remove the vehicle from the alignment rack.