Remove Components For Access

- Remove the front wheels (refer to procedure).

- Release the fasteners that secure the lower arch liners. Fold the arch liner forward to access the rear of the wheelwell.

- Lower the vehicle.

- Remove the 12V battery bracket beam (refer to procedure).

- Release the 2 fir tree clips that secure the 12V positive harness to the front crossmember.

- Move the 12V positive harness to the RH side of the vehicle to keep it out of the working area.

- Release the 4 bolts that secure the coolant reservoir to the front crossmember (torque 6 Nm). Do not remove the reservoir at this time.

Caution: At this point in the procedure, there are still 2 coolant hoses

and 1 harness attached to the reservoir.

- Carefully lift up the coolant reservoir and disconnect the coolant level sensor harness.

-

Ensure that the cap on the reservoir is properly secured, then pull the

reservoir forward into the underhood area.

Note: The reservoir hose is routed behind the drive unit hose. Note the routing of the hoses and ensure that they are routed correctly during reinstallation.

- Gently pull down on the 2 coolant hoses to release the clips (x4) that secure them to the front crossmember.

- Release the clip that secures the coolant reservoir hose to the A/C line.

- On the LH side of the 3-way fitting, clamp the coolant hose that leads to the differential housing. Remove the hose from the front drive unit and and plug the nipple.

-

Move the coolant reservoir to the LH side of the vehicle and secure it out of

the working area.

Caution: The reservoir is still secured to 2 coolant hoses.

-

On the LH side of the drive unit, clamp the coolant hose. Remove the hose and

plug the nipple.

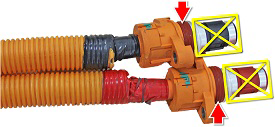

Tip: Use flexible hose clamp pliers to release the locking ring.

- Move the clamped drive unit coolant hose to the RH side of the vehicle so that it is out of the working area.

- Release the clip that secures the LH A/C line to the compressor HV harness.

- Release the 2 nuts that secure the A/C lines to the compressor. Plug both holes and cap both lines.

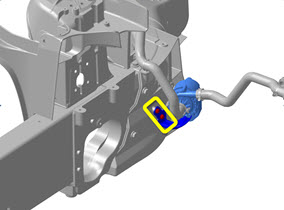

- Disconnect the compressor LV harness.

- Release the ground strap from the A/C compressor bracket (torque 7 Nm).

- Release the edge clip that secures the LV harnesses to the compressor bracket.

- Release the fir tree clip that secures the LV harnesses to the top of the front drive unit.

- Wrap the LV harnesses around the RH hood strut so that they are out of the working area.

-

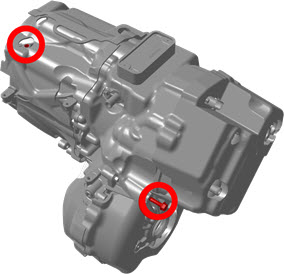

Have an assistant support the compressor. Release the 3 bolts that secure the

A/C compressor bracket to the front drive unit (torque 10 Nm).

Caution: Do not spill any oil when removing the compressor.

- Move the compressor and bracket to the RH side of the vehicle and secure them outside of the working area.

- Raise the vehicle.

Note: Perform the next 3 steps on both sides of the vehicle.

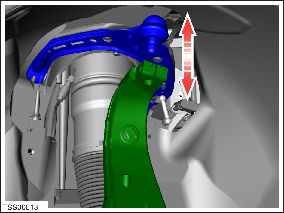

- Release the nut that secures the sway bar end links to the sway bar (torque 70 Nm).

- Release the wheel speed sensor harness from the brackets on the knuckle and the body.

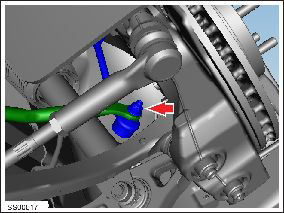

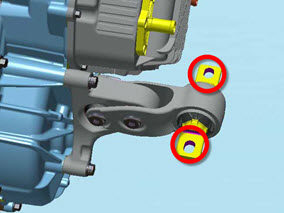

- Release the bolt that secures the upper control arm to the knuckle (torque 60 Nm).

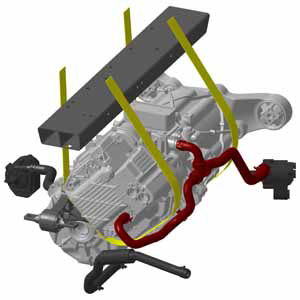

-

Temporarily lower the vehicle and remove the RH halfshaft from the

jackshaft.

Tip: Use a deadblow hammer to separate the halfshaft.

- Raise the vehicle to access the RH wheelwell.

-

At the rear base of the RH wheelwell, release and drain the coolant hose that

leads to coolant pump 4.

Note: This is necessary because the coolant hose and pump are removed with the drive unit.

- Release any clips that secure the coolant hose to the body.

- Lower the vehicle to provide easier access to the underhood area.

-

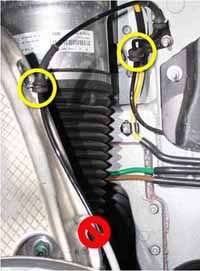

Working from the underhood area, release the 2 bolts that secure the bracket for

coolant pump 4.

Note: These bolts appear similar to other fasteners used in this procedure, but are slightly shorter. Ensure that the correct bolts are used during reinstallation.

- Release the straps that secure the lower RH section of the acoustic cover around the front drive unit. Remove only the lower RH section of the cover to access the drain plug.

- Set the fluid transfer pan into position beneath the drain plug. Ensure that the pan is level, then route the drain hose between the subframe and aeroshield so that it will drain into an oil drain pan.

- Remove the drain plug (torque 28 Nm).

- Release the 2 bolts that secure each fuse box to the front crossmember (torque 5 Nm). Move both fuse boxes behind the front crossmember.

- Release the bolt that secures the bracket for coolant pump 3 (torque 6.5 Nm). Move the bracket behind the front crossmember.

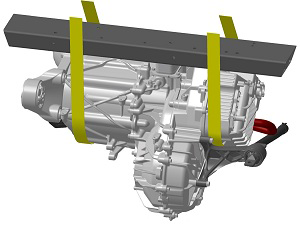

-

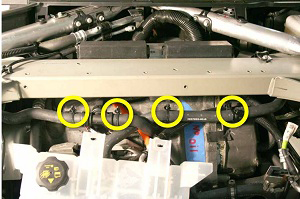

Release the 4 screws that secure the HV cables to the front drive unit (torque 7

Nm).

Caution: During reinstallation, carefully inspect the connector seals. If any are damaged, replace them.Caution: Apply P-80 emulsion to the connector seals on the HV cables before securing the HV cables during reinstallation.Caution: Do not apply P-80 emulsion to the HV terminals.

- Disconnect the motor logic connector.

- On the LH side of the underhood area, release the bracket from the body that secures the 4-way valve.

- Hand-tighten the drain plug and remove the fluid transfer pan.