-

Perform the vehicle electrical

isolation procedure (refer to procedure).

-

Remove the battery coolant heater (refer to procedure).

Caution: Do not allow coolant to spill onto the High Voltage Battery,

forward junction Box, DCDC Converter, battery coolant heater, or any

harnesses.

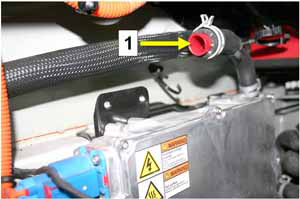

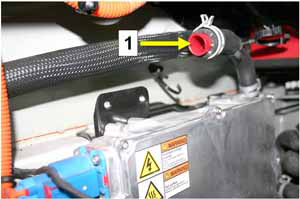

Note: After removing the heater, it might be helpful to plug the upper coolant hose

on the DCDC converter and remove the clamp. This provides additional clearance in

the working area to remove the DCDC converter.

Caution: Do not allow coolant to spill onto the High Voltage Battery,

forward junction Box, DCDC Converter, battery coolant heater, or any

harnesses.

-

Cut the zip tie that holds the top coolant hose to the firewall. Move the

coolant hose out of the way.

-

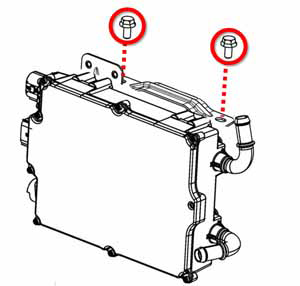

Release the 2 bolts that secure the bracket on the top of the DCDC converter to

the firewall (torque 22 Nm).

-

Release the nut that secures the bracket on the lower LH side of the DCDC

converter (torque 22 Nm).

Caution: This nut is very difficult to retrieve if dropped. It might

be helpful to use a magnet to hold the nut while it is being removed.

-

Release the 2 harnesses on the RH side of the DCDC converter.

-

Release the ground bolt (torque 25 Nm).

-

Release the 12V positive bolt (torque 13 Nm).

-

Release the fastener that secures the ground strap to the body (torque 9

Nm).

-

Remove the cable tie that secures the coolant hose to the lower

crossmember.

-

Place absorbent material in the base of the frunk to catch any coolant that is

spilled in the next steps.

-

Place a container in the frunk to catch coolant.

-

Gently pull the DCDC into the frunk area, but do not fully remove it.

-

Clamp the coolant hose close to the DCDC converter.

-

Release the locking clamp that secures the coolant hose to the DCDC converter.

Drain the coolant from the DCDC converter and from the hose into the container.