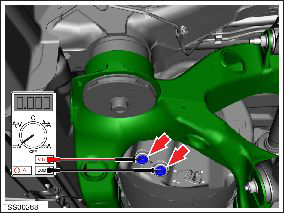

Checking for High Voltage at the Drive Inverter

Note: This procedure can only be performed on vehicles with the large rear drive unit.

If the vehicle has the small rear drive unit, perform the "Checking for High Voltage at the High

Voltage Junction Box (HVJB)" section of this procedure instead.

Warning: Proper personal protective equipment (PPE) and insulating HV

gloves with a minimum rating of class 00 (500V) must be worn while performing the

remainder of this procedure.

Warning: Ensure that the multimeter and leads are capable of handling at

least 500V.

Caution: To prevent future

water ingress, install new O-rings (1003784-00-A or later) on the drive inverter

cover and apply Silicone Lubricant (1010251-00-A) on both before installing the

cover. Insert the cover at an angle to prevent damage to the O-rings. Once the left

(B+) O-ring is seated, rotate the cover into position.