Installation procedure is the reverse of removal, except

for the following:

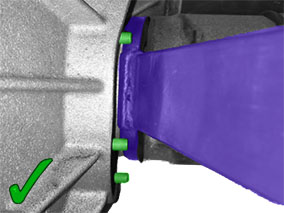

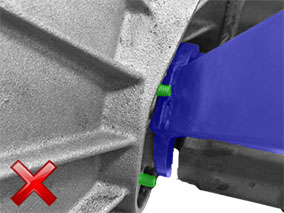

Caution: Ensure that the mating faces are clean and free from

debris.

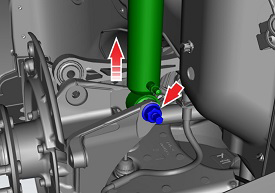

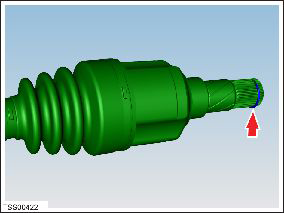

Caution: Do not reuse the snap-ring. Install a new

snap-ring before reinstalling the driveshaft.

Caution: Ensure that the bolt that secures the spring assembly to the

knuckle is inserted towards the rear of the vehicle; the head of the bolt faces the

front of the vehicle and the nut is tightened at the rear.

Tip: It

might be helpful to lift the lower control arm with a floor jack to line up the rear

suspension during reassembly. Do not torque the bolts at this time.

Caution: Only fully tighten suspension

nuts and bolts when the vehicle is on a 4-post lift and the suspension is in the

ride height position.

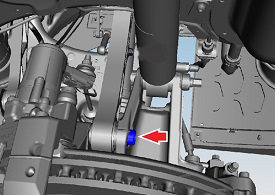

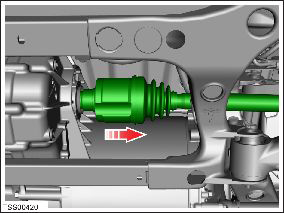

- When installing the driveshaft into the drive unit:

- Ensure that the opening of the snap ring is facing towards the

bottom of the drive unit.

- Do not damage or

displace the oil seal.

- Verify that the driveshaft is fully seated by carefully pushing

it into the drive unit until there is an audible "click" from

the snap ring.

- Check and top up gearbox fluid.

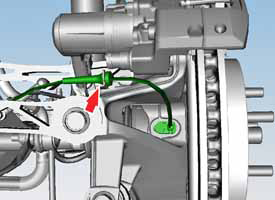

- Check the differential casing oil seal register for burrs and other damage.

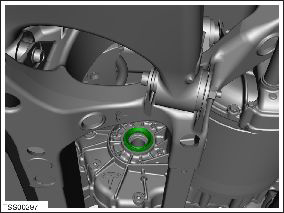

- Using the 1051509-00-A output seal installation tool, install a new output shaft

oil seal.