-

Remove the rear subframe (refer to procedure).

Note: Before continuing, move the subframe fixture to the gantry.

-

Disconnect the motor encoder.

-

Release the wheel speed sensor harnesses from the grommets on the

subframe.

-

On both sides of the subframe, release the bolt that secures the upper link to

the knuckle (torque 140 Nm).

-

On both sides of the subframe, release the bolt that secures the toe link to the

knuckle (torque 130 Nm).

-

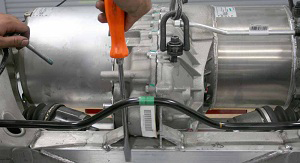

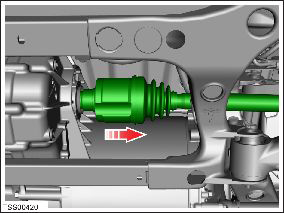

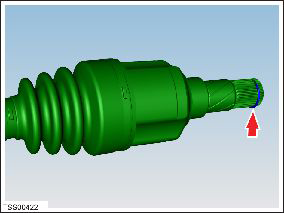

Use the axle extractor tool to release the driveshafts from the

transmission.

Caution: Ensure that the axle extractor tool does not contact any of

the differential retaining studs.

Caution: Do not let the driveshafts rest on the input seal.

Tip: It might be helpful to loosen the nut that secures the upper link

to the subframe. This provides additional clearance when installing the

driveshafts.

-

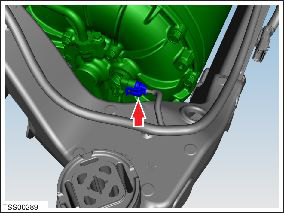

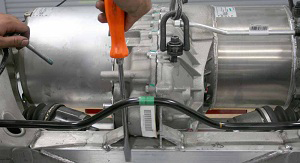

Secure the gantry bolts (x3) to the drive unit.

Note: Secure the short bolt to the motor section of the drive unit.

-

Loosen the nuts that secure the front and rear motor mounts to the subframe

(torque 90 Nm).

-

Loosen the bolts (x3) that secure the motor to the side motor mount. (torque 22

Nm).

Tip: It might be helpful to only use the gantry bolt that secures to

the motor. This allows the drive unit to be rotated to better align the bolt

holes.

Tip: When removing the bolts that secure the front and rear motor mounts,

it might be helpful to use a screwdriver or small prybar to pry against the

subframe. This helps to align the bolt holes in the motor mounts with the subframe

so that the bolts can be easily removed.

-

Remove the bolt that secures the front motor mount (torque 90 Nm).

-

Remove the bolt that secures the rear motor mount (torque 90 Nm).

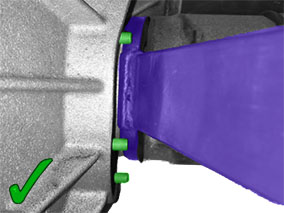

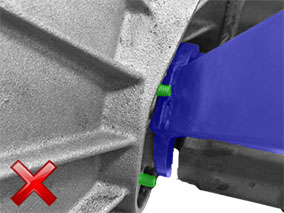

Caution: While lifting the drive unit assembly in the next step, have an

assistant brace a screwdriver or similar tool against the subframe and hold the

sway bar out of the way. Do not brace the tool against the motor mount.

-

Carefully lift the drive unit assembly, making sure to clear the rear of the

subframe.

Caution: Do not damage the motor encoder plastic housing.