Removal

- Recover refrigerant from the vehicle (refer to procedure).

- If the vehicle has air suspension, activate "Jack" mode on the touchscreen.

- Perform the vehicle electrical isolation procedure (refer to procedure).

- Remove the underhood storage unit for access (refer to procedure).

-

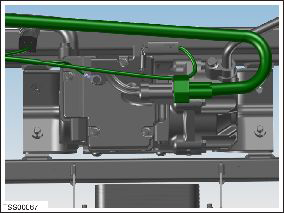

Disconnect the HV and LV harness connectors from the compressor.

Note: Remove and discard the HV connector label.

- Remove the bolt that secures the ground wire to the compressor (torque 9 Nm). Release the ground wire.

-

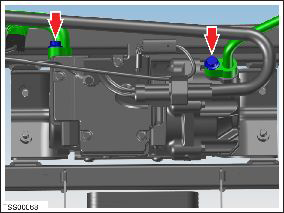

Remove the 2 bolts that secure the A/C suction and discharge lines to the

compressor (torque 10 Nm). Release the lines and remove the seals. Plug the holes.

Caution: The holes must be plugged to prevent contamination.Caution: Remove and discard O-rings.

-

Raise and support the vehicle (refer to

procedure).

Warning: Do not work on an incorrectly supported vehicle.

- Remove the front skid plate (refer to procedure).

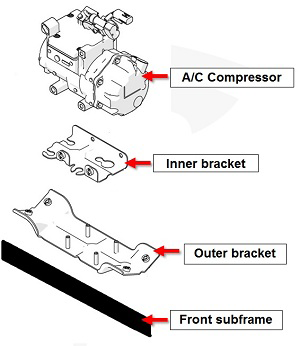

Note: The compressor mounts to an inner bracket, which attaches to an outer bracket.

The outer bracket mounts to the front subframe.

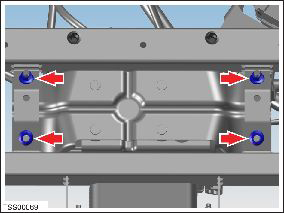

- Working beneath the vehicle, remove the nuts (x4) that secure the compressor and bracket assembly to the front subframe (torque 10 Nm).

- Lower the vehicle.

- Remove the compressor and bracket assembly.

- Remove the 2 bolts that secure the compressor to the inner bracket (torque 24 Nm).