Removal

Note: The slave charger is optional equipment. This procedure describes replacement

of a failed slave charger. To install a slave charger in a vehicle that is only

equipped with 1 charger, refer to Service Bulletin SB-13-44-010.

- Disconnect HV power, but leave 12V power connected. Perform the electrical isolation procedure (refer to procedure), except for the disconnection of the 12V battery ground.

- Connect an external charger to the 12V battery.

-

Remove the 2nd row seat frame:

- Standard seats: Refer to procedure.

- Executive seats: Refer to procedure.

-

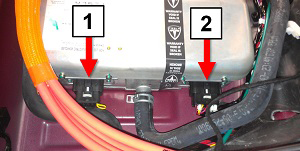

Disconnect the connectors (x2) from the side of the slave charger in the

following order:

Caution: Disconnecting harnesses in the wrong order triggers multiple high-priority alerts.

- Disconnect the 12-pin harness from the rear port.

- Disconnect the 10-pin HVIL loopback connector from the front port.

- Remove the HVJB cover (refer to procedure).

Warning: The previous step contains instructions to check for high

voltage inside the HVJB. Do not proceed unless no high voltage is present.

- Release the 4 harnesses that connect the HVJB to the chargers.

-

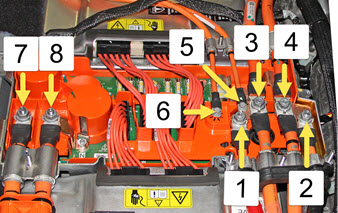

Release all fasteners inside the High Voltage Junction Box (HVJB) so that it can

lifted up in order to replace the charger in a later step:

- Dual motor vehicles only: Mark the rear HV cable that leads to the front drive unit as B-, and the forward HV cable that leads to the front drive unit as B+.

-

Release the 2 nuts that secure the HV cables that lead to the front drive

unit (torque 9 Nm).

Note: Refer to Table 1.Note: It is not necessary to replace the fastener(s) after it is removed. The threaded area has a reusable dry sealant, which looks similar to adhesive patch material.

-

Mark the rear HV cables that lead to the battery and drive inverter as B‒,

and the forward HV cables that lead to the battery and drive inverter as

B+.

Note: Refer to Table 1.

-

Release the 2 nuts that secure the HV cables that lead to the battery and

drive inverter (torque 9 Nm).

Note: Refer to Table 1.Note: It is not necessary to replace the fastener(s) after it is removed. The threaded area has a reusable dry sealant, which looks similar to adhesive patch material.

-

Mark the rear HV cable that leads to the forward junction box as B+ and

the forward HV cable that leads to the forward junction box as B‒.

Note: Refer to Table 1.

-

Release the 2 bolts that secure the HV cables that lead to the forward

junction box (torque 4 Nm).

Note: It is not necessary to replace the fastener(s) after it is removed. The threaded area has a reusable dry sealant, which looks similar to adhesive patch material.

-

Mark the HV cables that lead to the charge port:

- Single-phase charging: : Mark the forward cable as B- and the rear cable as B+.

- 3-phase charging: : Starting from the front and working toward the rear of the vehicle, mark the 4 HV cables that lead to the charge port from front to rear as L2, L3, L1, and N.

-

Release the bolts that secure the HV cables that lead to the charge

port.

- North America, Japan: 2 bolts (torque 9 Nm).

- Europe, APAC: 4 bolts (torque 4 Nm).

Note: Refer to Table 1.Note: It is not necessary to replace the fastener(s) after it is removed. The threaded area has a reusable dry sealant, which looks similar to adhesive patch material.

-

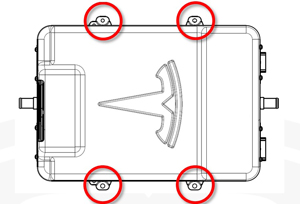

Release the 4 bolts that secure the HVJB to the body (torque 5 Nm).

Note: Do not remove the HVJB from the vehicle. It is only necessary to release the bolts so that the HVJB can be lifted up in a later step.

-

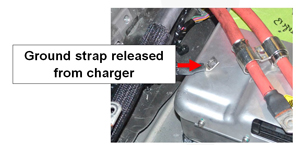

Release the ground strap from the rear of the charger (torque 7 Nm).

Note: Leave the ground strap secured to the vehicle.

- Dual motor vehicles only: Release the bolt that secures the fuse bracket to the slave charger (torque 9 Nm).

- Release the 4 bolts that secure the charger to the body (torque 7 Nm).

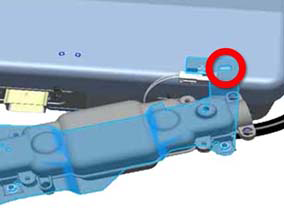

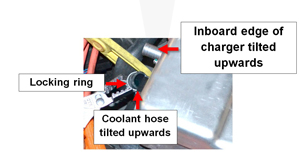

Note: It is necessary to lift the front of the HVJB out of the way in order to access

the inboard coolant hose. Have an assistant hold up the front of the HVJB 20-30

mm.

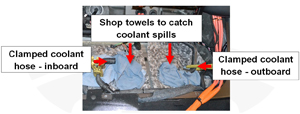

- Clamp the coolant hoses on both the inboard and outboard sides of the charger, approximately 150 mm from the edge of the charger.

- Ensure that all harnesses and cables are protected from any coolant that might be spilled in a later step.

- Lift up the inboard side of the charger. Cover the floor of the vehicle with towels or shop rags to catch any coolant that might be spilled in a later step.

- Remove the coolant plug from the inboard side of the new charger and have it ready before performing the next step.

- Tilt the inboard edge of the charger upwards. Use pliers or a similar tool to release the locking ring from the inboard coolant hose. Remove the coolant hose from the new charger and immediately install the coolant plug onto the old charger to stop coolant from spilling out.

- Repeat steps 10-13 for the outboard coolant hose.

- Lift the charger out of the vehicle.

-

If the charger is being shipped or stored, allow the coolant to drain from

the charger, then use compressed air lightly to blow out any remaining

coolant.

Caution: Do not exceed 25 PSI when using compressed air to blow out any remaining coolant.